Description

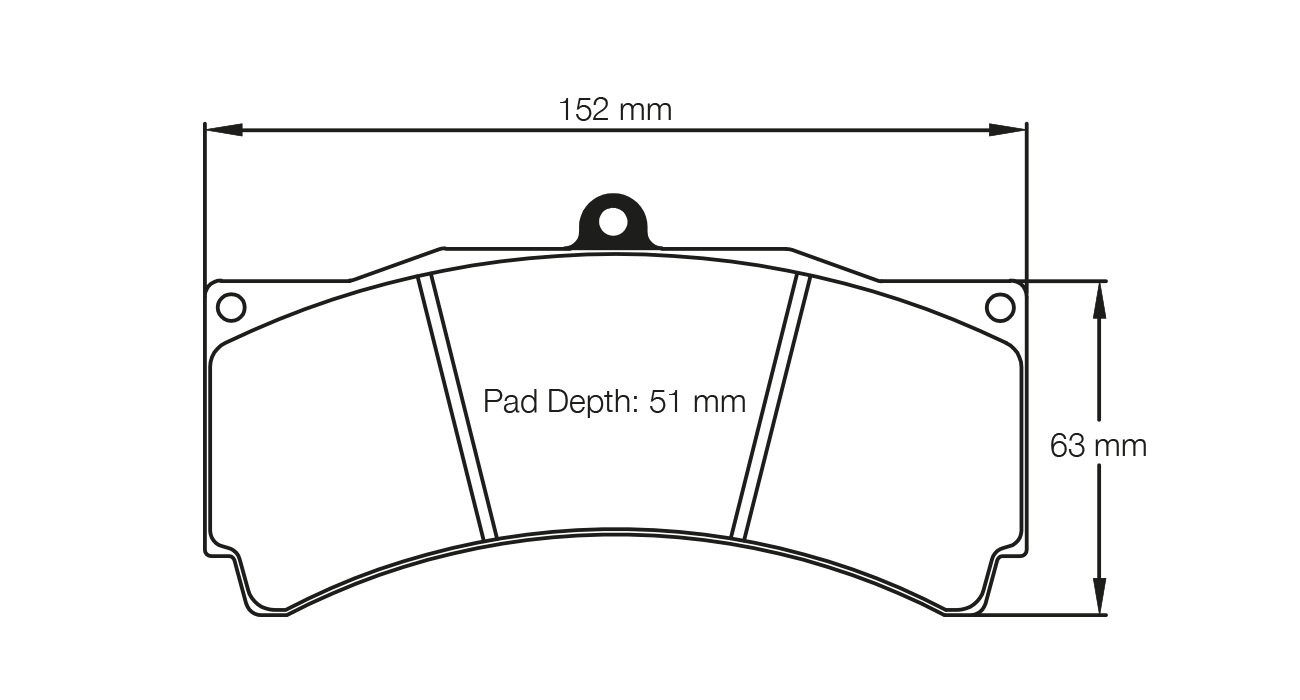

PAGID RACING SHAPE U1903

18mm thick

Will fit the following vehicles.

- Ford Mustang (Saleen S281 Extreme)

- Mitsubishi Lancer Evo X R4 Tarmac Rally

- Sin Cars R1

- Sin Cars R1 GT4

- Sin Cars R1 RS

Will fit the following vehicles.

- Alcon TA6, CAR89, CAR11 [4489] D51

- AP Racing CP3894 D46 / D51 / D54

- Baer Brakes 6S

- Coleman Series IV

- Stop Tech ST60

Available in the following compounds.

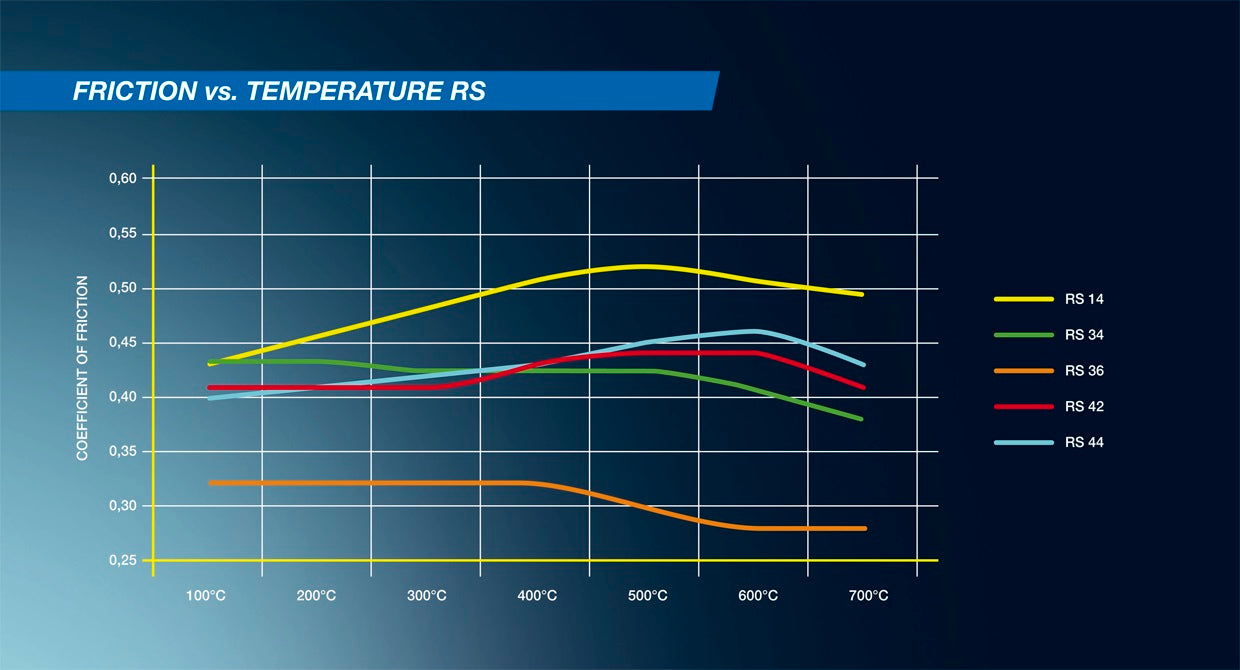

RS14

RS 14 features good all-round characteristics for many applications. It is a low metallic resin bonded material containing steel and aramid fibers.

RS42

RS 42 is a low metallic resin bonded material containing steel and aramid fibers. The characteristics make this material appropriate for small formula cars.

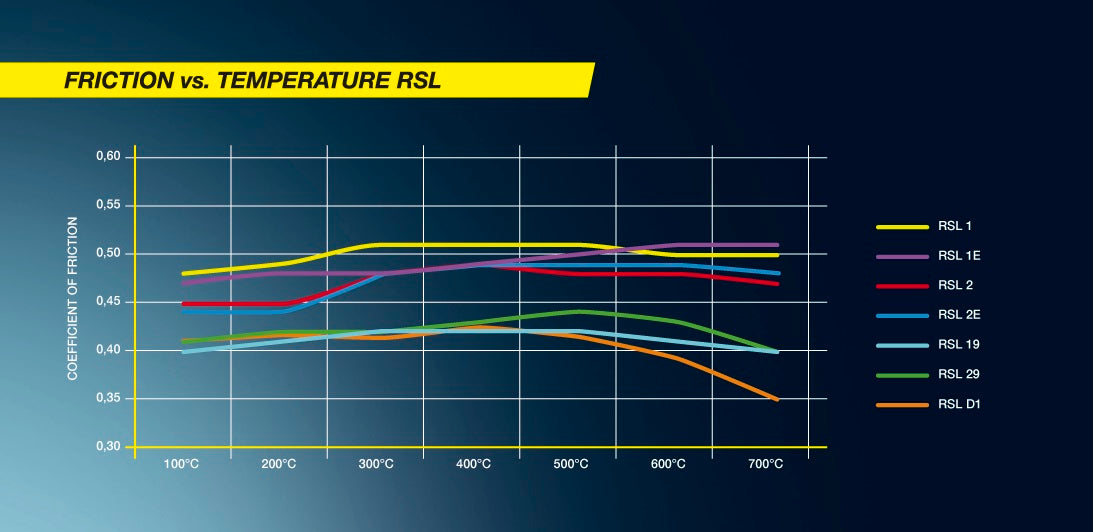

RSL1

RSL 1E and RSL 1 are low metallic resin bonded materials containing steel and aramid fibers with very high heat resistance. They maintain a constant friction level over a wide range of temperatures. Their reduced wear rate and disc friendliness make these materials appropriate for endurance races. RSL 1E is further improved in terms of pad life and modulation as well as friction stability at high temperatures and pad life. As a benefit, RSL 1E provides the lowest pad wear rate in the PAGID Racing portfolio for highly thermally loaded applications.

RSL29

RSL 29 features very good modulation and release characteristics. It is a low metallic resin bonded material containing steel and aramid fibers. The friction level of the material maintains constant at a low-medium level. Another advantage is the easy bedding in behavior.

RSL2

RSL 2E and RSL 2 are low metallic resin bonded materials containing steel and aramid fibers with high heat resistance. They maintain a constant friction level over a wide range of temperatures. Their reduced wear rate and disc friendliness make these materials appropriate for endurance races on applications with high cooling efficiency. RSL 2E is further improved in terms of pad life and modulation, as well as friction stability at high temperatures and pad life with optimized cooling.

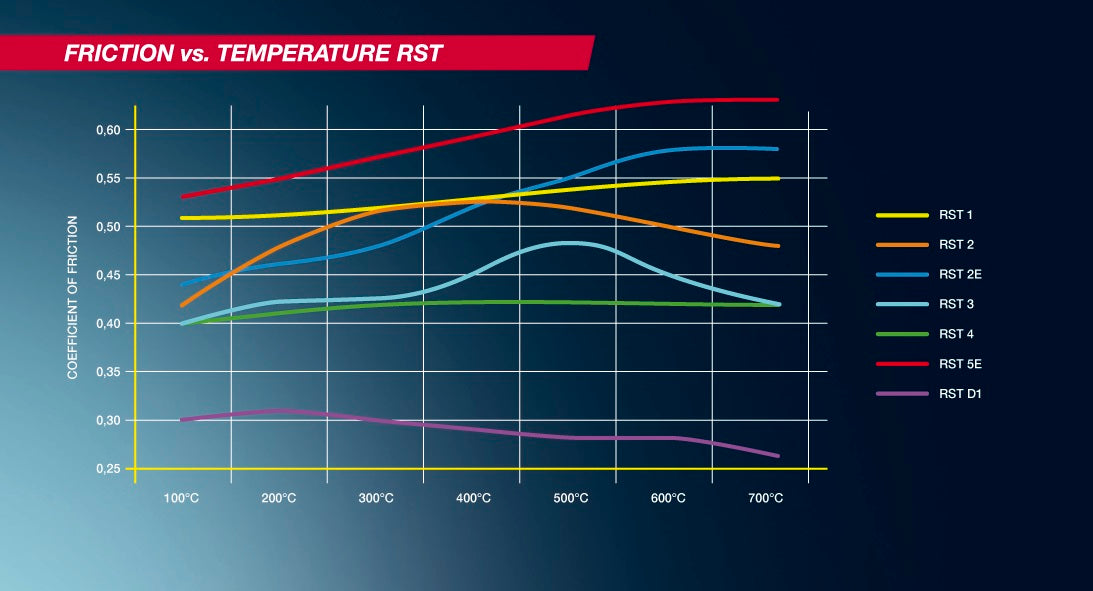

RST1

RST 1 has a very high friction level and high temperature resistance. It is a semi-metallic resin bonded material containing steel fibers. Cold friction and initial bite makes this material most appropriate for Rally and NASCAR applications.

RST3

RST 3 is a medium-high friction metal-ceramic compound containing steel fibers and is therefore the perfect complement of the RST product family. It captivates by its low heat conductivity.